Introduction to the Numerical Modeling

95% of industrial prototypes are digitally validated before physical production, drastically reducing lead times, costs and risks. The general public is often unaware of this, but every object around them - from the smartphone in their hand to the elevator they ride - has at one time or another been subjected to the scrutiny of digital simulation software. It's thanks to these simulations that a modern vehicle can withstand a crash, a building can stand up to an earthquake, or a pacemaker works in the human body with extreme reliability.

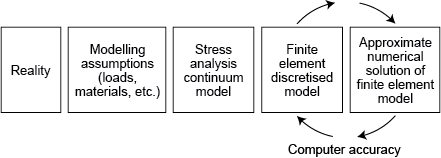

Numerical modeling is at the heart of all the great industrial, architectural and mechanical achievements that surround us. Whether to build a bridge, design an airplane or guarantee the safety of a child's toy, engineers use digital simulation methods to predict the behavior of an object or structure before it is even manufactured. The principle is simple in idea, but complex in execution: it involves translating a real-world system into mathematical equations, so as to understand how it will react to various stresses - weight, vibration, wind, earthquake, temperature, etc. These predictions enable us to design objects that will withstand the rigors of everyday use. These predictions enable us to design safe, functional and durable objects, while optimizing their cost and performance.

This “sizing” work is based on physical data (materials, geometry, usage constraints) and realistic assumptions about the environment in which the structure will evolve. A simple floor, for example, will have to be sized to resist its own weight, furniture, human movement, and even exceptional events such as an earthquake.

This approach consists of representing the elements of a system (such as mechanical structures, fluid flows or heat transfers) using mathematical equations, generally based on the fundamental laws of physics (Newton's laws, conservation of energy, laws of thermodynamics, etc.). Once these equations have been established, numerical methods (such as the finite element, finite volume or finite difference methods) are used to solve them approximately on a computer. This makes it possible to observe how a system will react to different stresses (shocks, loads, vibrations, temperature variations, etc.), without having to physically build the system or wait for the phenomenon to occur.

The main stages in a Numerical Modeling

1.Define the requirements and constraints: What does the structure have to do? What environment does it have to operate in? What permanent loads (weight, pressure) or variable loads (vibrations, temperature, impact) are to be expected?

2.Model the structure: Create a 3D model (CAD) of the system to be studied, which will serve as the basis for the simulation.

3.Choose the materials and physical properties: strength, elasticity, density, thermal or dynamic behaviour, etc.

4.Apply boundary conditions: Just as a light bulb is connected to a socket, every mechanical system has ‘inputs’ and ‘outputs’.

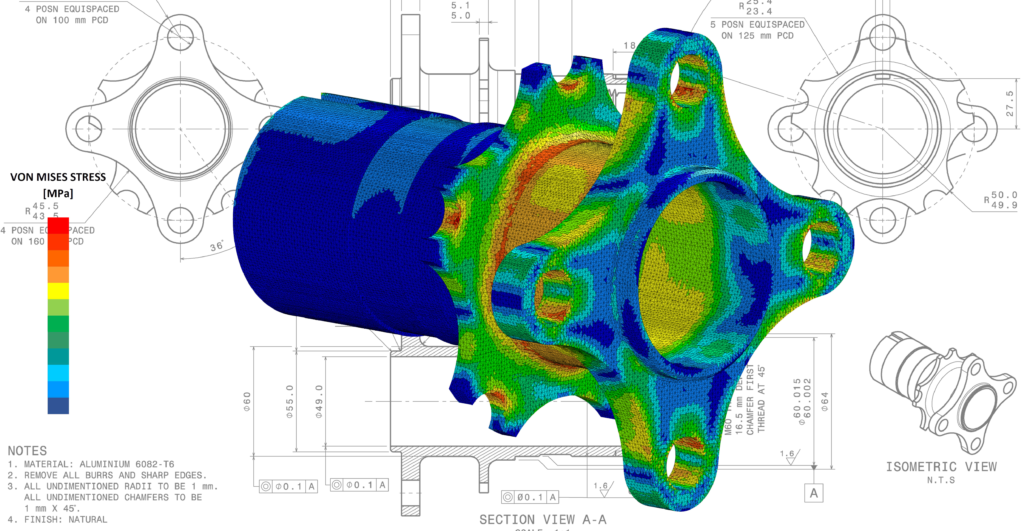

5.Discretize using the finite element method: The model is broken down into thousands of small elements (mesh), each of which is analysed individually.

6.Run the numerical simulation: Computer-aided calculation to solve all the equations. The more elements there are, the more accurate the calculation… but the longer it takes!

7.Analyse the results: Deformations, stresses, critical zones, risks of failure or instability. Engineers can then adjust the model to achieve the desired objectives.

8.Optimise and validate: Adjustments to reduce weight and costs, or increase service life while maintaining safety. This stage may also include physical tests to validate the model.

Numerical modeling has become an indispensable tool in all sectors where reliability, performance and safety are paramount - from aeronautics to civil engineering, not forgetting the automotive, energy and medical sectors. Thanks to it, engineers can design structures that are more complex, lighter, more economical… but above all safer. What we call ‘digital’ is ultimately the computer's ability to solve, on a large scale, very concrete problems using small pieces of mathematical truth. And behind every well-designed product or infrastructure, there is almost always a well-conducted numerical modeling.